Special Lubricants.

We are Manufacturer, Supplier, Exporter of Sintered Transmission Parts, Sintered Automotive Parts, Sintered Couplings, Sintered Sliders, Sintered Flanges, Sintered Levers, Sintered Piston Cooling Nozzles, Sintered Governor Weight Supports, Sintered Clutch Plates, Sintered Gears, Sintered Pressure Plates and our setup is situated in Kolhapur, Maharashtra, India.

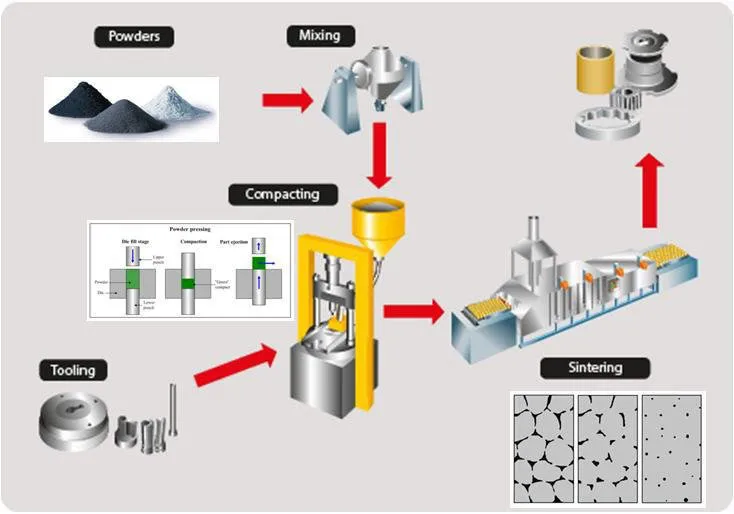

The powder metallurgy process is a simple and straight process but it has to be administered in a very methodical and meticulous manner. The process has been very well established and being updated day by day- the thrust being continuous improvement.The technical and commercial advantages of producing parts through the powder metallurgy process are that it offers a unique opportunity to produce close to exact size components cost effectively. Also it facilitates producing high density parts to low density parts like self lubricating bushes.

The Process Includes

-

A. MIXING

-

B. COMPACTING

-

C. SINTERING

-

E. HEAT TREATMENT

-

F. STEAM TREATMENT

-

G. OIL IMPREGNATION

-

H. SECONDARY OPERATIONS

Design Facility

Latest computer aided design facility with 2D and 3D

simulations are utilized for the designing of tooling

elements.

Tool Room Facility

Our manufacturing process is backed by an in-house tool room which is fully equipped for developing all types of die tools required for our manufacturing.